How To's

How to identify & replace your VFD

Technological products are meant to be replaced. There is no exception to this no matter how little it is used or how well maintained it is. This applies to all products including Variable Frequency Drives (VFD).

Hitachi Variable Frequency drives when properly installed, can last a very long time depending on environment load and frequency of use. Even when these drives last a long time there are often other reasons to replace Variable Frequency Drives. Some examples are technological improvements, emergency situations and attached product lifecycle completion.

Before further reading, we recommend reading our previous blog post regarding VFD selection and Accessory use and selection.

What is a product lifecycle?

Any product has a product lifecycle. In the case of Variable Frequency Drives, this lifecycle typically lasts around 15-20 years with periods of Active, Mature and Discontinued. Any user planning to purchase a drive must purchase a unit that is within the active product lifecycle. A product within the active product lifecycle ensures the user that product support and spare parts are available for that certain unit.

A mature product on the other hand may still be purchased with caution. A product in this period means that it will enter the discontinued phase after several years. Additionally, a product within the mature phase has its support and replacement parts limited.

A discontinued product however is a product that is not anymore manufactured. With Hitachi Drives, a discontinued product remains covered with an active support. In some cases, discontinued products may still be manufactured in an order basis which increases the cost dramatically.

Ideally, any user wants the Variable Frequency Drive to cover all phases of the product lifecycle. With this, it can be said that the product’s operational lifespan has been maximized.

What are the common reasons for Drive Replacement?

In some situations, a Variable Frequency Drive may not operate at the designed lifespan. This may be caused by variety of reasons such as:

– Deterioration

– Malfunction

– Error

These are some of the emergency cases which may push to immediate Drive Replacement.

Additionally, there are non-emergency situations that may also require Drive replacements. This may include:

– Process improvement / Enhancement

– Efficiency

– Control inadequacy

Given the reasons, what are the options for drive replacement?

Generally, there are Two (2) drive replacement methods such as Direct Replacement and Migration.

Direct replacement refers to the replacement of the drive with the same exact unit. This method requires less engineering work as the replacement drive’s mounting specifications and wiring method are typical however, this only works for Variable Frequency Drives that are in active product lifecycle. It may also work with discontinued drives but the user must have the same unit within the company’s spare parts inventory which means, the replacement has been ordered prior to drive maturity or discontinuation.

Migration is basically replacing the drive with an equally approved unit. This pertains to shifting to a different drive category with a product that is capable of providing the minimum or higher functionalities provided by the old drive.

Direct replacement is simple to perform. Migration offers more challenge from selection, installation and commissioning of the Variable Frequency Drive. With this, an understanding of the drive parameters are important.

What are advantages of Migration?

Drive migration may be difficult to implement but it offers more advantages compared to simple drive replacement. Some of these advantages include:

Updated Technology

Migrating enables the user to utilize the newer technological offers and advancement that the latest drive models offer. Newer products, at a minimum, may retain the capabilities of predecessor products however, most updated drive models are simply equipped with an improved version of the old technology.

Improved Reliability

Product feedback, field performance, bugs, and other product reviews of the old VFD product were used as a reference in building the newer VFD model. With this, known product anomalies are expected to be corrected in the latest drive models thus, lowering chances of errors and increasing uptime and reliability.

Ease of Maintenance

Product information on newer drive models can be easily obtained in different ways. Additionally, latest drive models have an active customer support and spare parts in active manufacturing and distribution. Should maintenance experience drive malfunction, information can be easily gathered and if component or product replacement is needed, it can be sourced out from the distributor or directly from the manufacturer.

Lower Cost of Ownership

As replacement parts and accessories for newer drive models are actively available, it can be expected that the cost of these components are within reasonable range compared to obsolete parts of discontinued products which are mostly made to order or refurbished. With this, maintaining newer drive models in operation costs significantly lower compared to keeping discontinued products functioning.

Hitachi Variable Frequency Drives Replacement

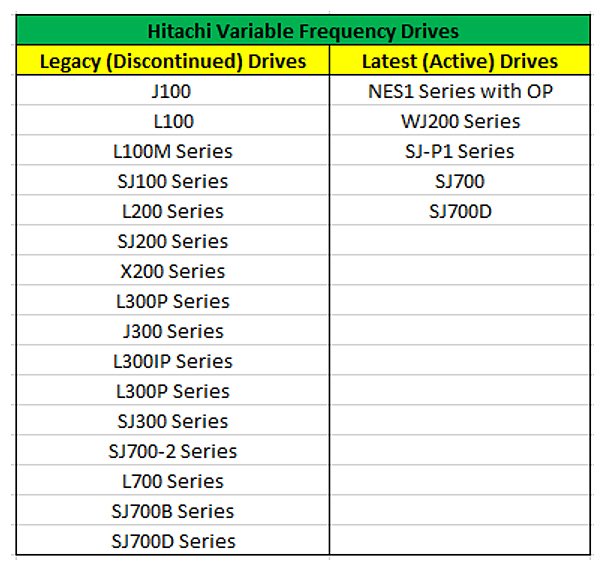

Hitachi Variable Frequency Drives are designed with continuity. This means, drive models especially legacy or discontinued drives may be upgraded to active drive product categories.

Whether direct replacement or migration, user must determine first, the parameters supported by any VFD unit which can be identified by inspecting the drive’s model name indication.

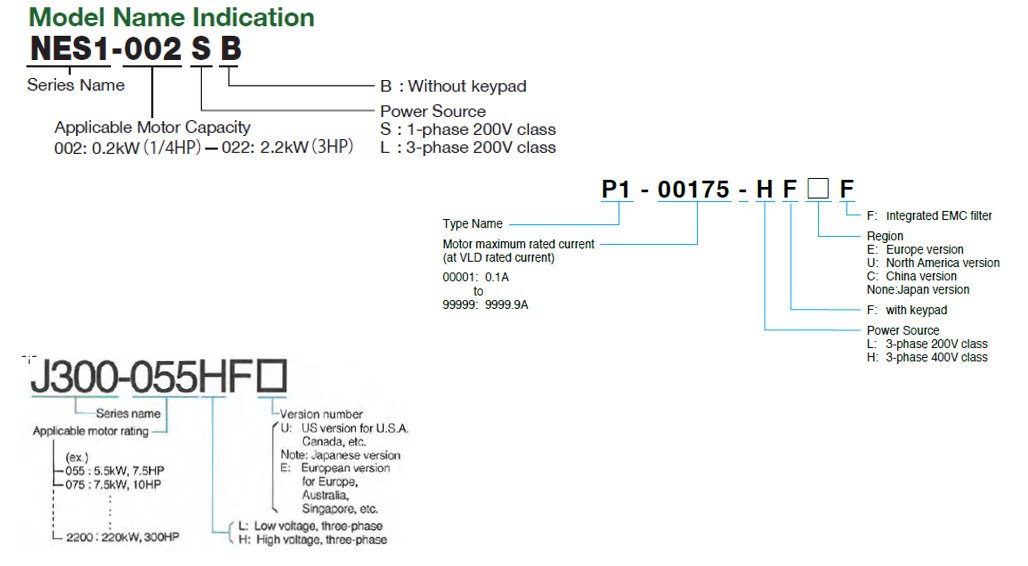

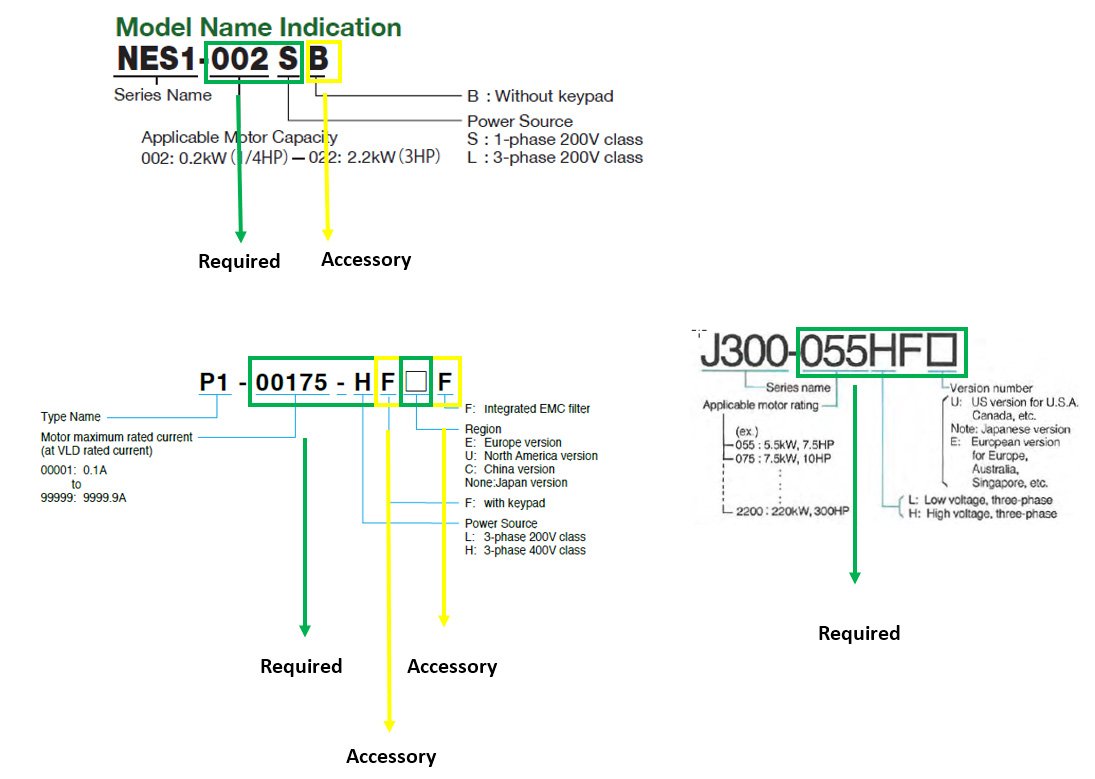

Hitachi Variable Frequency Drives model name indication are consistent in providing the Drive Series, Motor Capacity, and Power Source. Some drive model indication additionally depicts information regarding Version number, Integrated keypad, Region and Integrated EMC filter.

The following are the explanation of model name components:

Series or Type name

This component points to the drive category or series. It is usually the first letters in the mode name indication.

Motor Capacity or Rating

Succeeding the series name is the Motor capacity or rating. This information is used to determine the compatible motor rating. This is cross checked against the motor’s nameplate to properly size the VFD. For more information, you may read this blog post.

Power Source

Power source refers to the voltage category that is required to operate the drive. Hitachi Variable Frequency Drives are designed to operate with 1-Phase and 3-Phase supply, with voltage class of 200VAC (Low Voltage Class) and 400VAC (High Voltage Class). Some 3-Phase rated drives are also compatible with 1-Phase operation however, these drives operate with derated functionality.

When using a 3-phase drive into 1-phase supply, the rule of thumb is to DOUBLE the Full Load Current (FLA) to account for the excess current in the diode module created from the single phase to three phase conversion.

Keypad

Are also known as Operator Interface Terminal (OIT). Keypad allows user to locally configure and control the VFD. Some keypads are also provided with parameter copy and download function which allow parameters of a drive to be copied and downloaded to another unit.

Region / Product Version

Some drives models are especially designed for a specific region such as American, European and Japanese. This is due to different existing standards that must be complied with.

Integrated EMC Filter

EMC filters reduces conducted noise on the power supply line generated by the inverter. Some drives do not an integrated EMC filter while some have.

Drive Replacement Guide

As previously mentioned, Direct Drive replacement and Migration are the available replacement methods.

There is not much to discuss with Direct drive replacement as this method is very straightforward. With Migration, cross-over to different category is imperative.

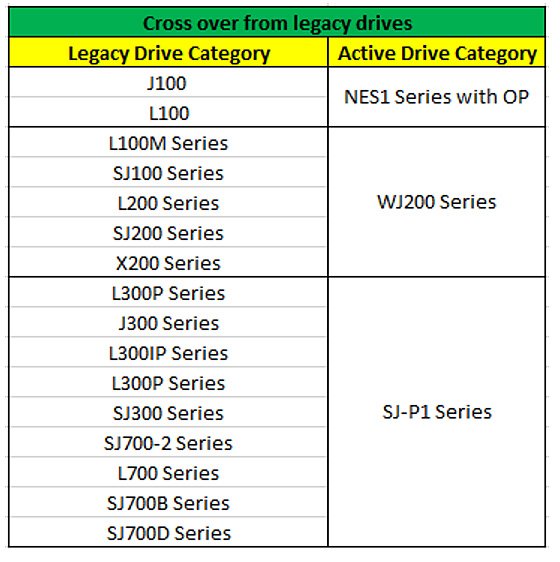

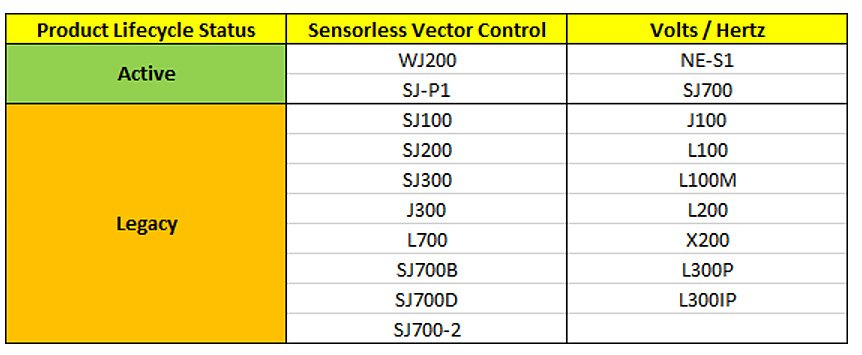

Hitachi Recommended category migration is provided in the table below:

The provided table helps any user to quickly identify the appropriate migration series. Once identified, user may now proceed with the next migration steps. Just a note, these migration steps are not exactly sequential, it mostly depends on the user requirement and familiarity with the product.

When selecting the specific product under a category or drive series, there are certain selection criteria that must be followed, and some considered. These are:

1. Model name indication

Ideally, the parameters of the replacement drive must meet the parameters of the old drive or as close as possible.

How can this be done?

Identify which component are necessary and which component are accessories. For Instance, you would not want to replace a 5HP drive legacy with a 2.5 HP Active drive. Similarly, you would not want to replace a 3-Phase 400VAC legacy drive with a 1-Phase 200VAC drive. These parameters are necessary, thus, require direct matching. However, a legacy drive with an integrated EMC filter can be possibly replaced with an Active drive that has no integrated EMC filter. EMC filters are accessory components that can be installed separately. This is true with keypad and other accessories as well.

2. Drive control method

Drive control method of the replacement drive must be equal or better than the old drive. Control method selection includes Sensorless Vector and Volts / Hertz control. These control methods are directly related to the output Torque whether, constant and variable Torque, so, this must be followed. Additional selection factors are the control algorithm supported by the drive such as Proportional + Integral + Derivative (PID) and Fuzzy Logic.

3. I/O interfaces

Input and Output interface of the replacement drive must be able to cater the existing I/O devices wired to the old drive. These I/O interface may include but not limited to LOC / REM, START/STOP, FORWARD / REVERSE, ANALOG SPEED REFERENCE, ANALOG SPEED FEEDBACK.

4. Communication Interface

Most drives have standard RS485 communication interface. If drives are monitored and controlled over this communication network, the replacement drive must be capable of the same communication feature. If drive is a stand-alone installation, communication interface is optional.

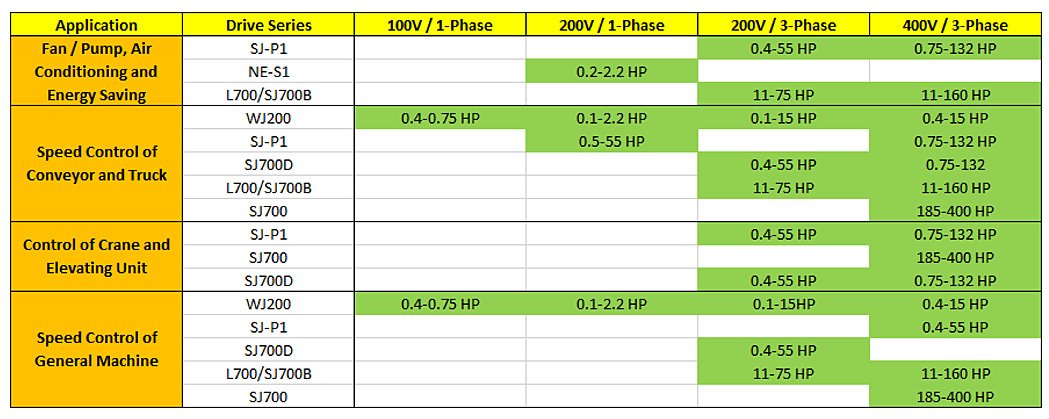

5. Intended application

Intended application of the replacement drive must be the same or supported by the replacement drive. Selections include Fan and Pump applications, speed control of conveyor and truck, crane and elevating unit and speed control of general machine.

6. Regenerative Converters

If your drive is connected to Regenerative Converters, this means it is attached to a DC Voltage grid. Ensure that your replacement drive is compatible to the regenerative converter unit and the drives installed in this RCU grid.